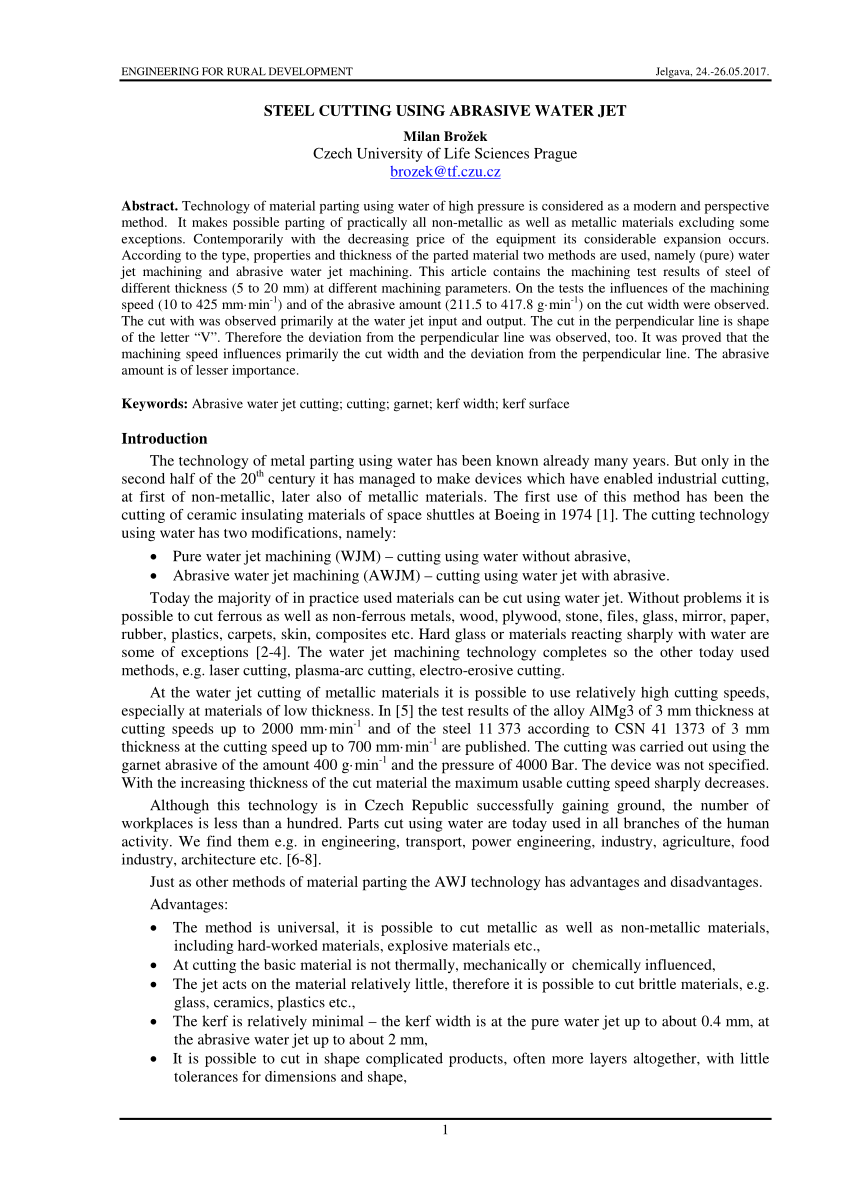

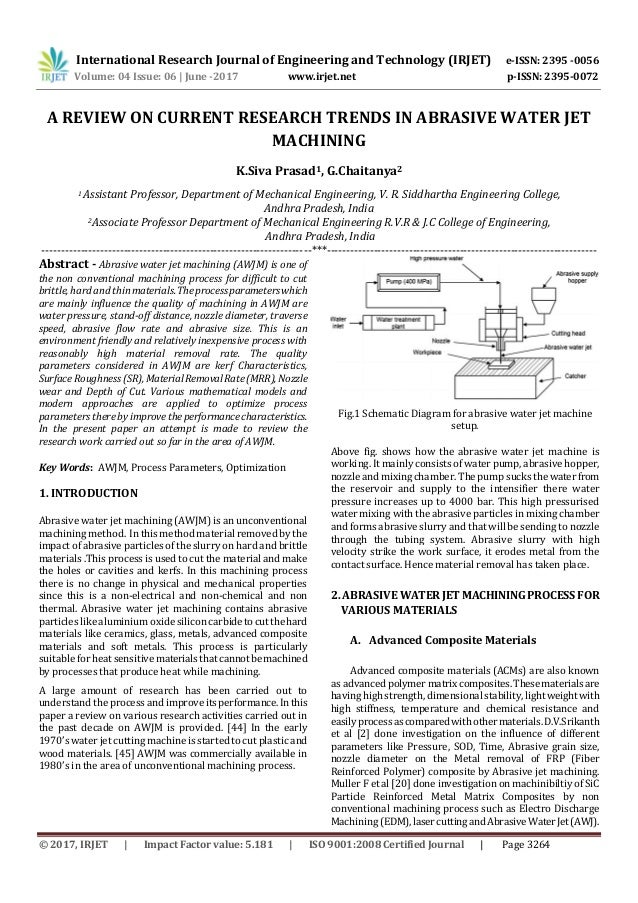

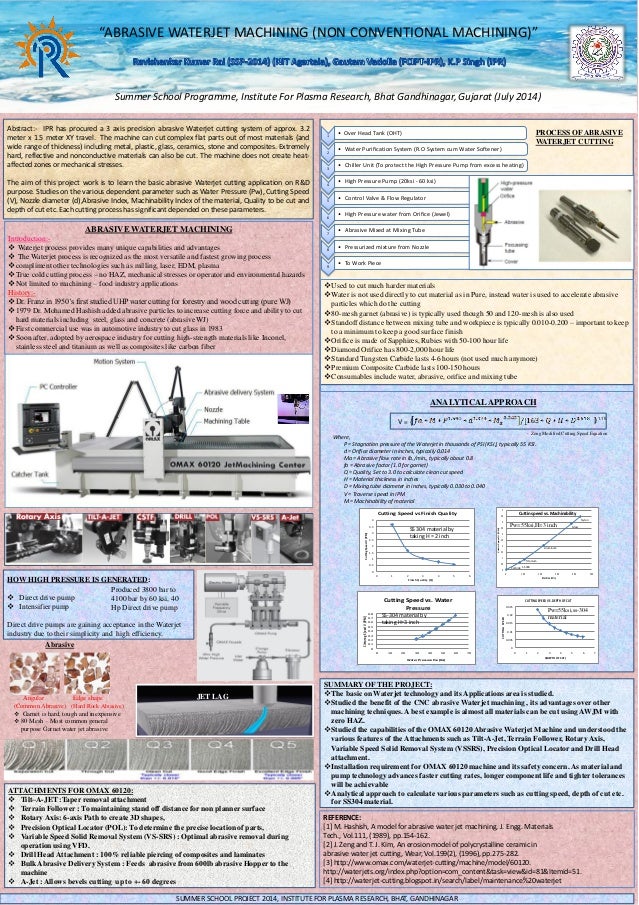

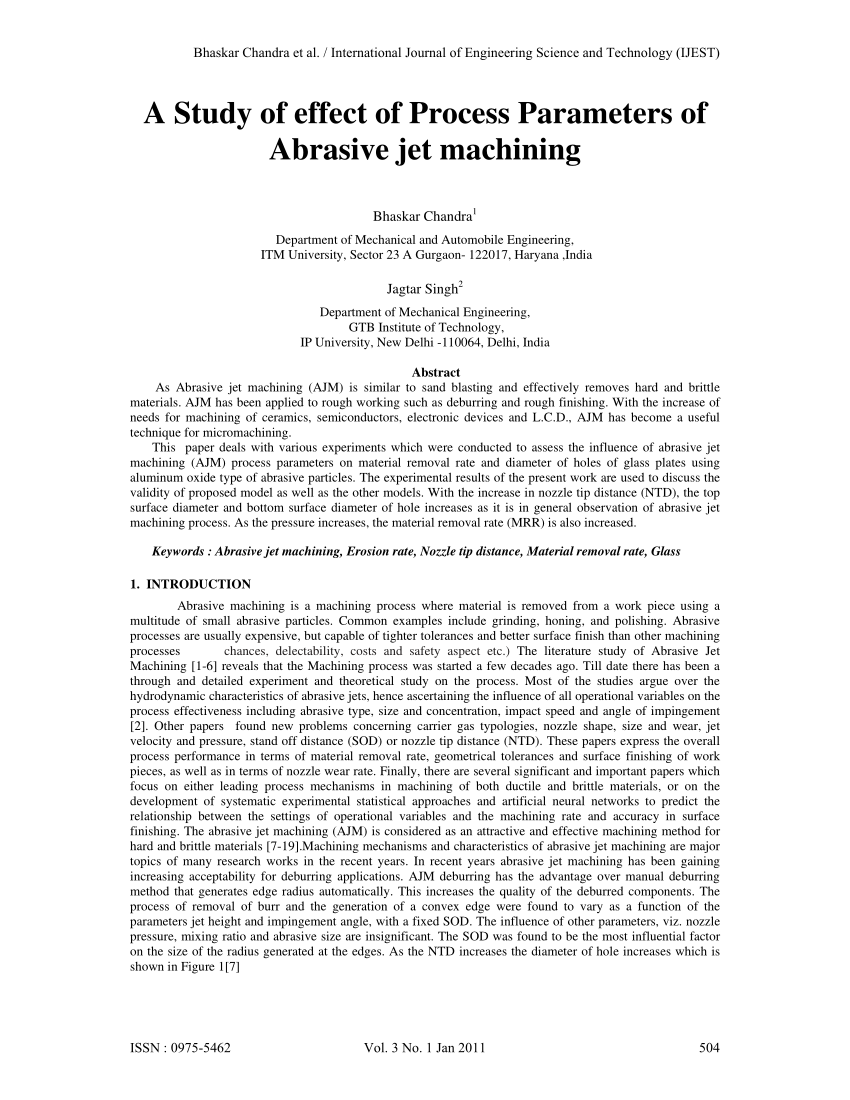

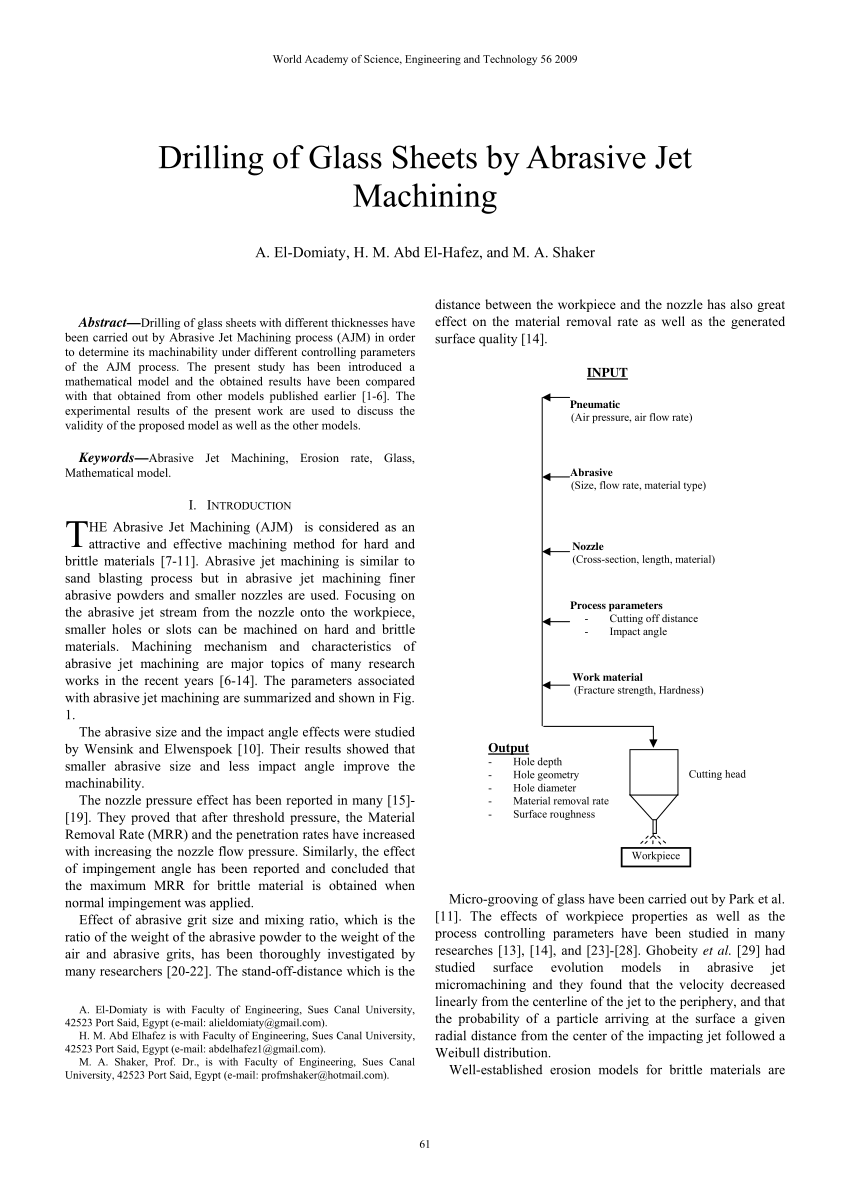

The term abrasive jet refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal or granite while the terms pure waterjet and water.

Abstract for water jet cutting technology ppt.

Typical water jet cutting machines have a working space from few square feet to hundreds of square feet.

Water jet technology gives us an opportunity to put these cost cutting capabilities to work.

In this moment the high pressure water pumps are available from 276 mpa up to 689 mpa.

This article reviews the characteristics of this new technology and its usage in laser.

Water jet guided laser cutting technology is a relatively new technology which utilizes a water jet and laser beam pulsed nd.

Pure water cutting pure waterjet is used mainly for relatively soft materials such as plastic textiles paper sealing materials metalic foils.

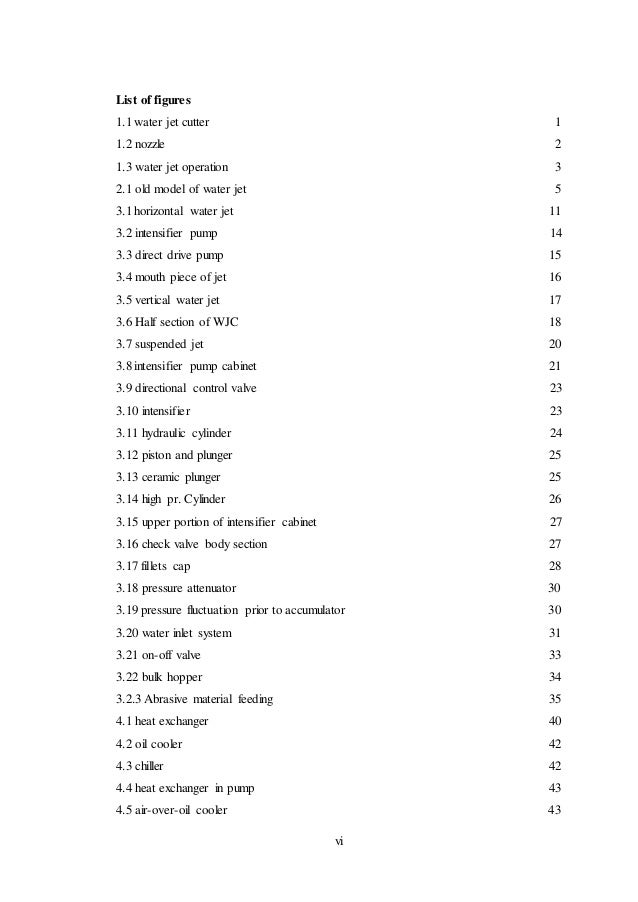

Project report on water jet system 1.

1 chapter 1 1 1introduction a water jet cutter also known as a water jet or water jet is an industrial tool capable of cutting a wide variety of materials using a very high pressure jet of water or a mixture of water and an abrasive substance.

Beyond cost c utting the water jet pro cess is recognized as the most versatile and fastest growing.

In the food sector for example it is used for cutting cheese fruit or vegetables.

Other materials are carpets textiles fibrous materials or insulating materials.

Fast extreme water jet cutter machine working modern technology waterjet cutting compilation.

Plastic materials to be separated can be foils and seals.

Also explore the seminar topics paper on waterjet cutting with abstract or synopsis documentation on advantages and disadvantages base paper presentation slides for ieee final year mechanical engineering me or production automobile students for the year 2019 2020.

Water jet cutting a technology on the rise october 2010 page 7 5.

In 1983 flow international introduced abrasive water jet cutting which allowed the water jet to be effectively used for the cutting of metals 235.

The technology is able to cut with high precision without blurs.

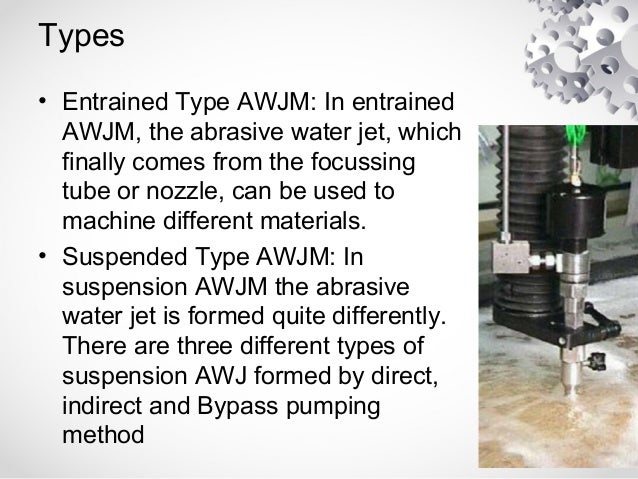

A abrasive water jet cutting system 6.

It also produces less heat and pollution at the cutting zone unlike conventional machining.

A water jet cutter also known as a water jet or waterjet is an industrial tool capable of cutting a wide variety of materials using a very high pressure jet of water or a mixture of water and an abrasive substance.

Two types of cutting let us take a closer look at the basics of the two waterjet cutting methods.

B the principle of operation of the abrasive water jet nozzle.

Water jet cutting with pure water is mainly suitable for cutting soft materials such as food foams papers or plastics.

Pressure water jet approximately 50 000 psi as a water only cutting tool primarily for use in furniture manufacture.