Exposure to north light in the northern hemisphere or a light box with appropriate wavelength light of the required intensity may be used for color sensitive products but the majority of accelerated testing is carried out at increased temperature typically 35 40 c.

Accelerated shelf life testing protocol.

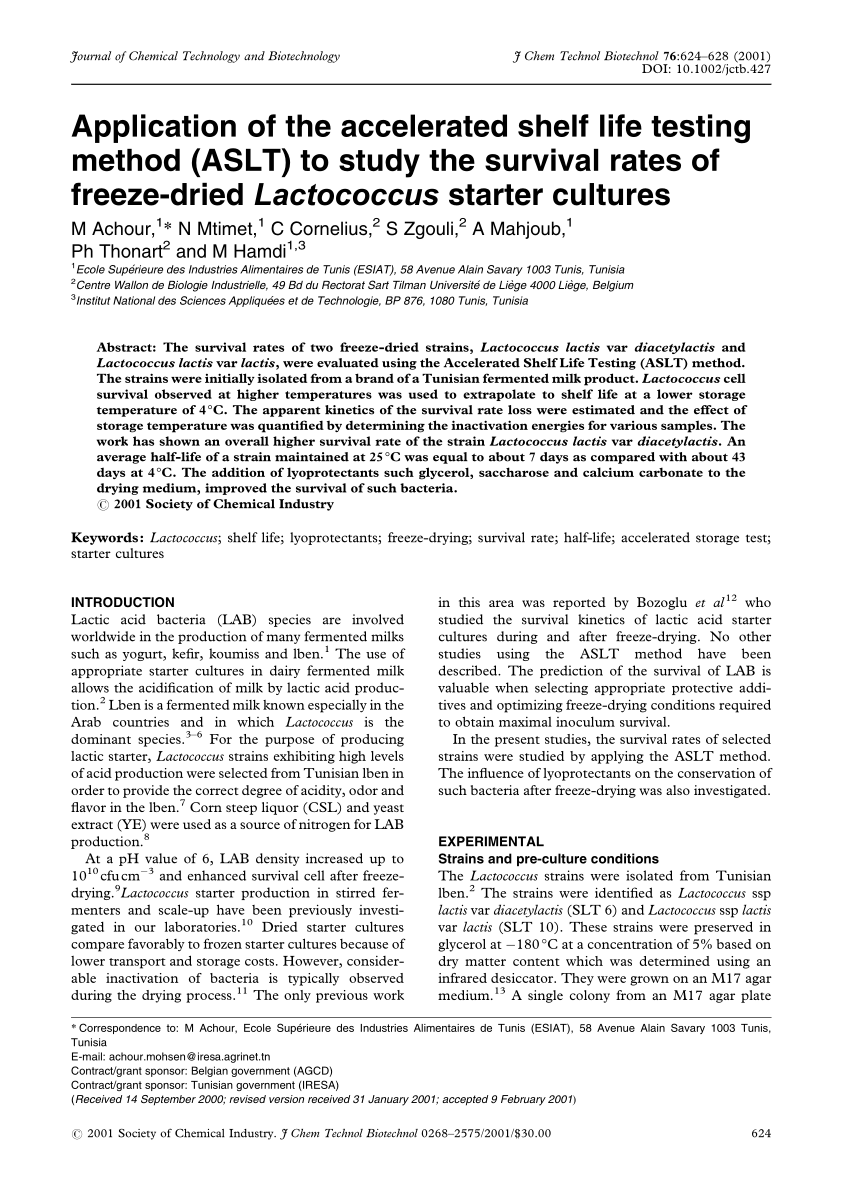

In these studies accelerated conditions i e.

The institute of food science and technology defines shelf life as the period of time during which the food product will remain safe.

The number of days that the product remains stable at the recommended storage conditions is referred to as the shelf life.

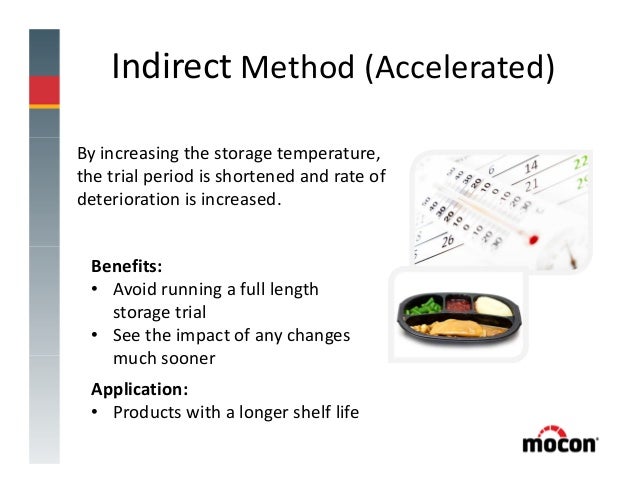

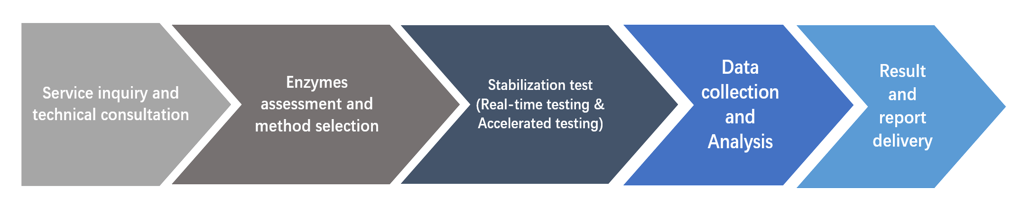

Real time assessment is usually time and resource consuming.

The product is then evaluated at specific intervals to monitor any potential degradation in quality or food safety.

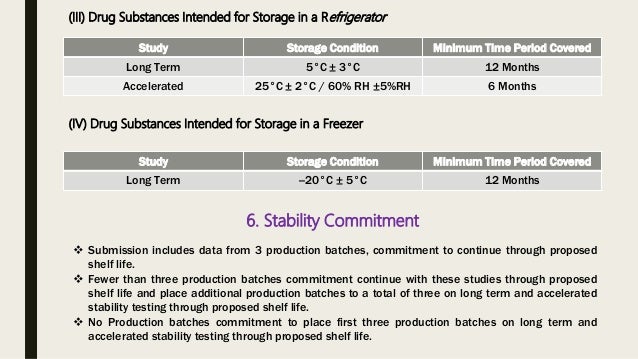

Using state of the art stability chambers our shelf life testing protocols ensure that products are kept at specific temperatures and humidity levels throughout the duration of the study.

The food industry has a great need to have a shelf life test in the minimum time possible because of the fierce competition sudden shortage of agricultural inputs opportunity loss and low unit value of the commodity.

40 deg c relative humidity.

Accelerated shelf life testing is often employed to obtain advance indications of the performance of newly formulated products and products destined for tropical markets.

Scope of astm f 1980 provides information for developing.

It can notbe used to test for microbial growth.

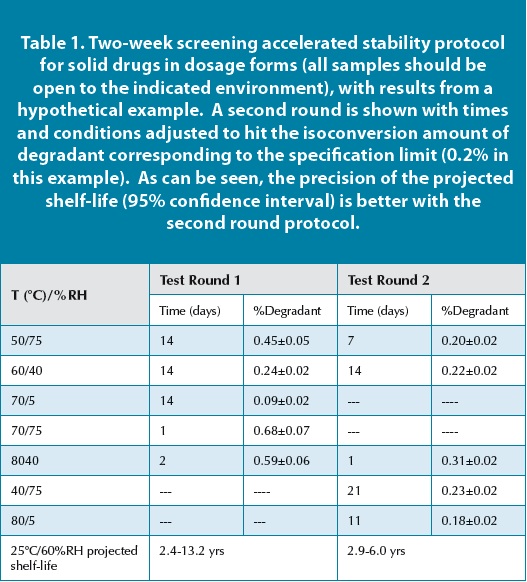

Elevated temperature are applied to eligible products to predict product shelf life at typical storage conditions.

What is an accelerated shelf life study.

Corradini and peleg 2007.

Shelf life studies can come in many different forms including accelerated studies.

If properly applied this procedure known as accelerated shelf life testing aslt allows estimation of the shelf life data at storage conditions usually experienced by the product on the market by using data acquired at accelerated storage conditions labuza and schmidl 1985.

Accelerated studies will assess changes in moisture content water activity oxidation of fat and sensory characteristics.

Where appropriate comply with any label.

A non guideline accelerated storage stability and corrosion characteristics study can be used at the registrant s discretion to fulfill data requirements for storage stability.

Biopharmaceutical products in storage change as they age but they are considered to be stable as long as their characteristics remain within the manufacturer s specifications.

Typically 12 week accelerated shelf life temperature.

This process is performed using the q10 value.

Most package shelf life validation protocols.

Be certain to retain its desired sensory chemical physical microbiological and functional characteristics.

Aslt is a form shelf life assessment.

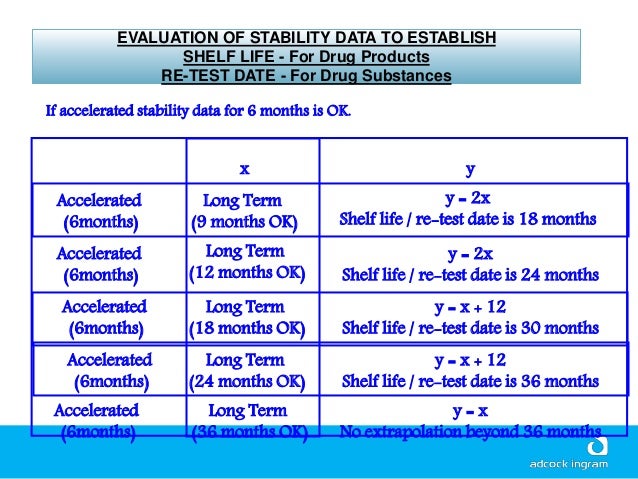

Stability testing using accelerated aging protocols shall be regarded as sufficient evidence for claimed expiry dates until data from real time aging studies are available.

75 for some or all of the following tests.

This approach is particularly advantageous for those products that are characterized by a long shelf life such as ambient stable and frozen foods.