The common and conservative means of the accelerated aging calculation is based on the arrhenius equation which states that a 10 c increase in temperature doubles the rate of chemical reaction.

Accelerated shelf life testing formula.

Shelf life is commonly estimated using the results data generated from both real time and accelerated shelf life testing.

Accelerated life testing is the process of testing a product by subjecting it to conditions stress strain temperatures voltage vibration rate pressure etc in excess of its normal service parameters in an effort to uncover faults and potential modes of failure in a short amount of time.

Accelerated aging temperature c typical values are 50 c 55 c and 60 c.

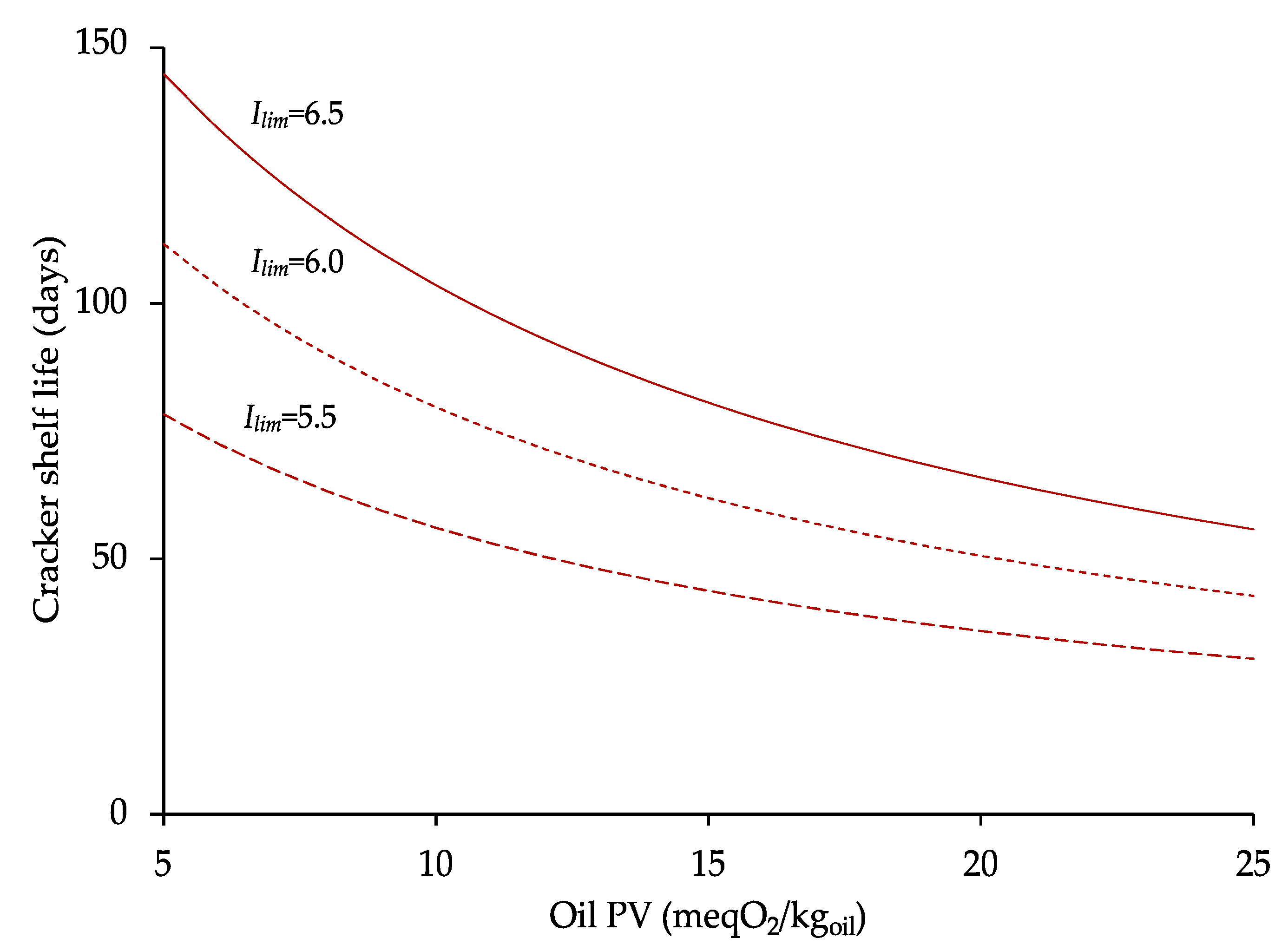

Typically a q10 value of 2 is used as an initial shelf life estimate but this may not represent the actual acceleration factor of a specific food product.

For example storage at a higher temperature can result in a prediction in say.

It is used to simulate real shelf life aging and is conducted to validate shelf life claims and document expiration dates.

Shelf life to be simulated days days.

Type the target shelf life days 2.

Storage temperature to be simulated c typical values are between 20 c and 25 c c.

Accelerated shelf life testing aslt kilcast and subramaniam 2000 can be incredibly useful when setting a shelf life for an ambient product as the developer does not need to wait for the whole of the product s shelf life to determine the end of shelf life.

Accelerated aging time calculator astm f1980 07.

Real time assessment is usually time and resource consuming.

The food industry has a great need to have a shelf life test in the minimum time possible because of the fierce competition sudden shortage of agricultural inputs opportunity loss and low unit value of the commodity.

It is recommended that accelerated shelf life studies be accompanied by a shelf life study conducted under normal storage conditions in order to determine the actual q10 value.

In real time stability testing a product is stored at recommended storage conditions and monitored until it fails product specifications.

By analyzing the product s response to such tests engineers can make predictions about the service.

In accelerated stability testing a product is stored at elevated stress conditions.

Values above 60 c are not recommended.

The accelerated aging process is based on the relationship of temperature and reaction rate where an increase in temperature increases the reaction rate.