11 31 2 process description1 7 the process description is broken into three distinct segments discussed in the following sections.

Abrasive cutting wheel manufacturing process.

Grain processing 3 05 036 for bonded abrasives manufacturing and 3 05 037 for coated abrasives manufacturing.

Steel cut off wheel cutting wheel cutting disc manufacturer supplier in china offering 5 inch cutting disc for steel abrasive cutting wheel cut off wheel 125x1 0x22 2 mpa abrasives cutting wheel 230x2 5x22 2 and so on.

It is a cutting tool in which millions of microscopic abrasive grains are bond together.

White paper examines the use of superabrasives in foundries discover the benefits of using norton winter ironclad superabrasive wheels in foundry applications given the industry trend toward modernization and.

We are the indian manufacturer of cutt of wheels which make fast clean cuts in ferrous metals and stainless steel with these abrasive cut off wheels.

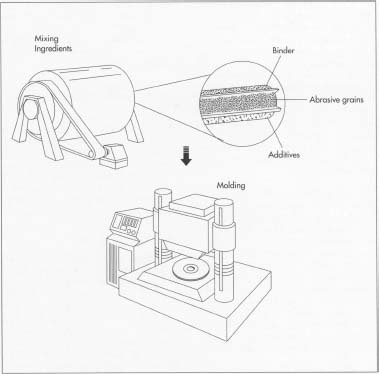

As shown in the image the abrasive grains are held together in the porous structure of the grinding wheel by a bonding substance bond.

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.

Learn more about the numerous backing types used in the manufacturing of coated abrasive products for wide belt applications.

Production of the abrasive grains production of bonded abrasive products and production of.

Grinding wheels are made of natural or synthetic abrasive minerals bonded together in a matrix to form a wheel.

4 5 inch cut off wheel this 4 5 inch cut off wheel have the best sharpness character and longer using life.

Hand cranked knife sharpening stones grindstones handheld power tools such as angle grinders and die grinders.

While such tools may be familiar to those with home workshops the general public may not be aware of them because most have been developed and used by the manufacturing industry.

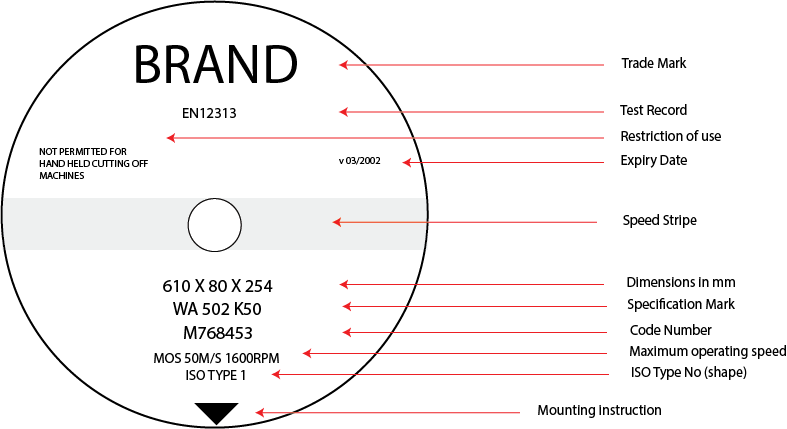

The power tool industry uses a specialized system of terms to organize and name abrasive grinding wheels and cutting wheels.

Here each abrasive grain acts like a spiky tool.

Abrasive grains and bond are the primary components mixed together in the grinding wheel manufacturing process but depending on the grinding needs other additives such as sawdust crushed nut.

Like most other power tool accessories abrasive wheels are available in a huge variety of types and styles suited for different applications and most of these types and styles are separated by only small variations in materials and design features.

A wide variety of machines are used for grinding.